The resistance observed by the movement between two surfaces is termed as Friction. The Friction between polymer surfaces. High friction can result in difficulties with winding of film rolls, bag production and packaging operations

There are several factors affecting the development of friction including:

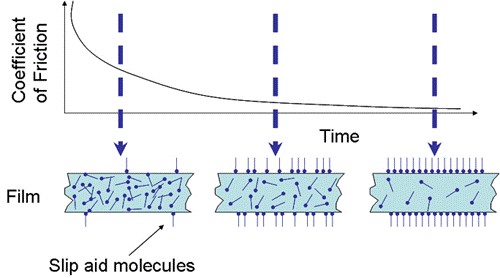

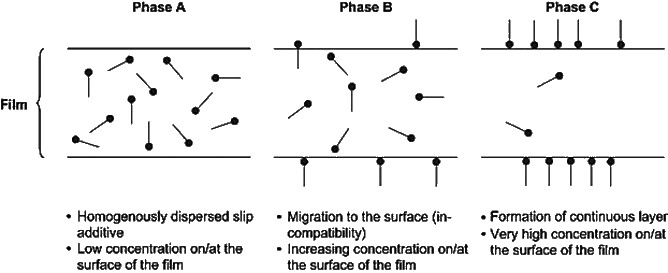

The low molecular material easily migrates to the outer surface of the product immediately after machining and form a favourable gliding layer on the film surface, but high concentration may affect the printing on the product. The product uses slip additive that makes surface smoothly slides at time of contact. For the packaging industry, often uses waxes, such as ecuramide, ethylene Bis(streamside), Silicones in Polyethylene and Polypropylene resin.

* Note: Get TDS/MSDS on request