Antiblocking Masterbatch (PP & PE)

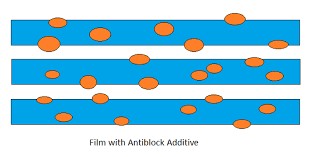

Antiblocking means Creating Roughness on plastic surfaces:

- Reducing the film-to-film block force

- Support the easy machining process

- Overcome the blocking force between two film surface in the film rolls makes them tightly bind together, it is difficult to separate them. This happens due to affinity for each other, opposite charge, due to vacuum.

This phenomenon causes many difficulties in the production process:

- It makes it difficult to put the material inside the bag, sometimes causing loss due to spillage.

- Difficult to open the packaging bags mouth, causing time consuming.

- The anti-clumping agent makes the surface of the membrane slightly rough, so that air can easily interfere with the membranes that helps reduce the vacuum effect. In some special cases, the antistatic component is added, thanks to the entering of air, the steam will together and block the charge on the membrane surface. Thereby eliminating the clumping phenomenon that has elements due to charge.

- The composition of the antiblocking could be either inorganic or organic material in polymer.

- Organic & Inorganic: CaCO3, Silica, Talc, polymer or Silicone beads etc depending on the thickness of the membrane, different inorganic particles are required.